自动凉茬机的粉碎才能是指单位时间内粉碎物料的多少其单位一般用:吨/小时。影响自动凉茬机的生产能力的要素有许多,比如:

The crushing capacity of the automatic stubble cooler refers to the amount of crushed materials per unit time, which is generally used in tons per hour. There are many factors that affect the production capacity of the automatic stubble cooler, such as:

1、粉碎设备的粉碎件(锤头、鄂板)的耐磨性越好粉碎才能越大,假如不耐磨,将影响粉碎能力。

1. The better the abrasion resistance of the crushing pieces (hammerheads and jaw plates) of the crushing equipment, the greater the crushing capacity. If they are not abrasion resistant, the crushing capacity will be affected.

2、物料的硬度。越硬的物料粉碎起来越困难,自动凉茬机,并且对设备的磨损越---。粉碎的速度慢,当然粉碎能力就小。

2. The hardness of the material. The harder the material is, the more difficult it is to crush it. The automatic stubble cooler will wear the equipment more. The crushing speed is slow, of course, the crushing capacity is small.

3、物料的湿度,即物猜中含的水分较大时,物料在打茬机内简单粘附,也简单在下料运送过程中堵塞,造成粉碎能力减小。

3. The humidity of the material, that is, when the moisture content in the material is high, the material simply sticks in the stubble machine, and also simply blocks during the blanking and transportation process, resulting in reduced crushing capacity.

4、自动凉茬机粉碎后物料的细度,细度要求高,即要求粉碎出来的物料越细,则粉碎能力越小。

4. The automatic stubble cooler requires high fineness of materials after crushing, that is, the finer the materials crushed, the smaller the crushing capacity.

5、打茬机物料的组成,粉碎前物料里含的细粉越多越影响粉碎,因为这些细粉简单粘附影响运送。对于细粉含量多的应该提前过一次筛。

5. The composition of stubble machine materials, the more fine powder contained in the materials before crushing, the more impact on crushing, because the simple adhesion of these fine powder affects transportation. Those with a large amount of fine powder should be screened in advance.

6、物料的粘度。即物料的粘度越大,越简单粘附。

6. The viscosity of the material. That is, the greater the viscosity of the material, the simpler the adhesion.

在酿酒生产过程中广泛运用自动凉茬机,制酒自动凉茬机,在谷类堆积后入窖前务必进行配糟、加曲的实际操作,在这儿此外务必将温度降入窖的适合温度。您有需求就来我们网站

http://www.qfrtrq.com进行咨询!

Automatic stubble cooling machine and automatic stubble cooling machine for liquor making are widely used in the process of liquor making. The actual operation of preparing grains and adding koji must be carried out after the grains are stacked and before they are put into the cellar. Here, the external temperature must be reduced to the appropriate temperature for entering the cellar. Come to our website if you need http://www.qfrtrq.com Consult!

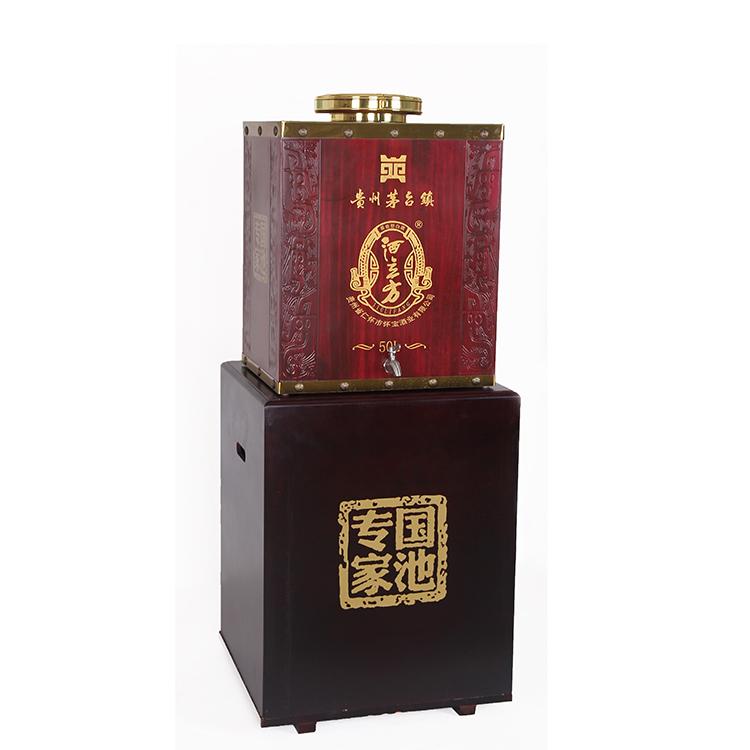

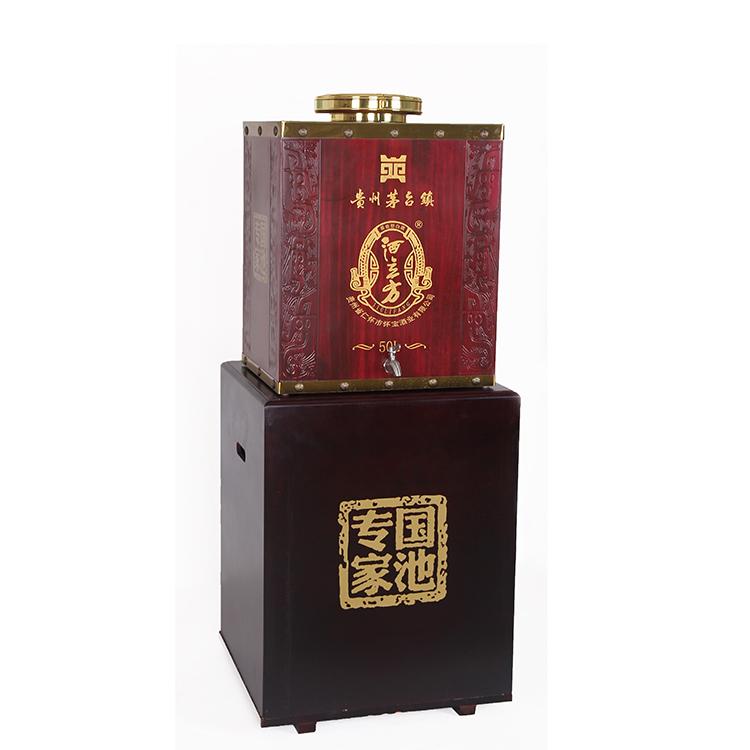

自动售酒机 2024-07-25

自动售酒机 2024-07-25  不锈钢酒桶:关于酒桶你需要知道的一切 2024-07-19

不锈钢酒桶:关于酒桶你需要知道的一切 2024-07-19  不锈钢酿酒桶大解析! 2024-07-13

不锈钢酿酒桶大解析! 2024-07-13  不锈钢酒罐的产品概述及特点 2024-06-13

不锈钢酒罐的产品概述及特点 2024-06-13  大型酿酒设备有哪些组成? 2024-06-10

大型酿酒设备有哪些组成? 2024-06-10  自动售酒机的产品特点 2024-06-07

自动售酒机的产品特点 2024-06-07  白酒酿酒设备知识介绍 2024-06-04

白酒酿酒设备知识介绍 2024-06-04  全自动凉茬机的使用故障有哪些? 2024-05-24

全自动凉茬机的使用故障有哪些? 2024-05-24  不锈钢内胆实木酒桶:木酒桶如何储存葡萄酒? 2024-05-23

不锈钢内胆实木酒桶:木酒桶如何储存葡萄酒? 2024-05-23  自动售酒机有哪些功能 2024-05-22

自动售酒机有哪些功能 2024-05-22  全自动凉茬机的工艺流程以及组成 2024-05-21

全自动凉茬机的工艺流程以及组成 2024-05-21  不锈钢内胆实木酒桶:不锈钢材质的优势 2024-05-20

不锈钢内胆实木酒桶:不锈钢材质的优势 2024-05-20